Pre-Fabricated PVC TPO Corners for Single-Ply Roof

Our collection of pre-fabricated TPO details/PVC details is engineered to eliminate the complexities and potential failures associated with field-fabricated flashings. Manufactured from high-quality

TPO PVC membrane, these components are ready to be heat-welded directly to your TPO roofing system and PVC rooing system , creating a monolithic, durable, and fully watertight barrier.

· Seamless Integration: Made from the same high-quality TPO /PVC material as our membranes, ensuring perfect chemical and physical compatibility. They heat-weld together to form a single, homogeneous layer.

· Unmatched Consistency & Quality: Factory-controlled manufacturing guarantees uniform thickness, precise angles, and consistent quality, far superior to on-site fabrication.

· Dramatically Reduced Installation Time: Pre-formed shapes mean no cutting, folding, or guessing. Simply position and weld. This saves significant labor hours and gets your project watertight faster.

· Enhanced Reliability & Performance: Eliminate common weak points in roofing systems. Our prefabricated details are designed to withstand thermal movement, UV exposure, and harsh weather conditions, providing long-term peace of mind.

· Wide Range of Applications: Ideal for all commercial, industrial, and institutional buildings requiring a reliable and efficient single-ply roofing solution.

Features

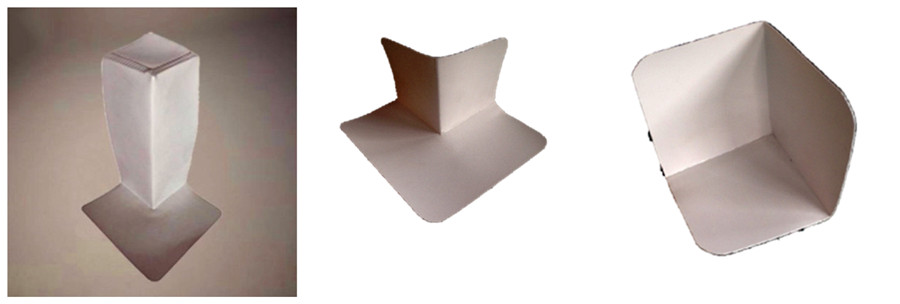

Product Range Includes:

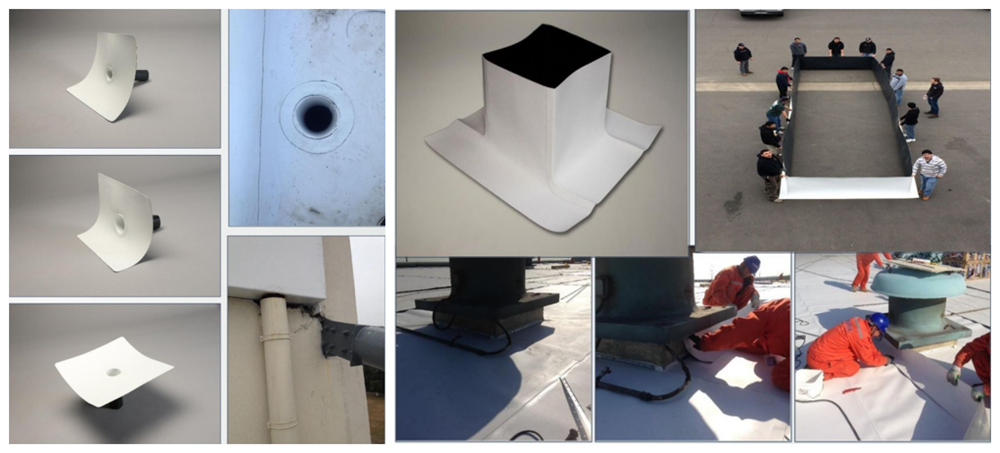

· Pipe Boots: Available in various sizes to fit standard roof penetrations. Ensures a perfect seal around pipes, conduits, and vents.

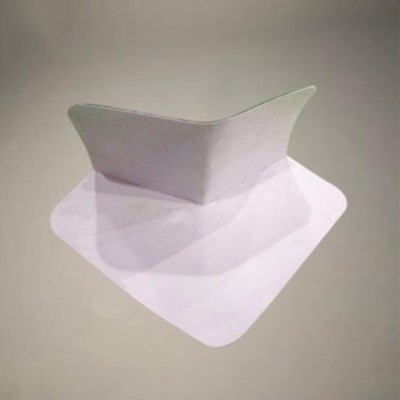

· Inside & Outside Corners: Pre-formed 90-degree corners for perfect seals at parapet walls, expansion joints, and other wall-to-roof transitions.

· Drain Sumps & Flashings: Specifically designed to create a robust, leak-proof seal around roof drains, the most critical detail in any roofing system.

· Custom Prefabricated Details: We can manufacture custom shapes to meet the specific requirements of your project.

Application Scope

In the process of waterproof construction, prefabricated accessories can be used to properly handle some detailed places

, which can avoid potential leakage and greatly improve the effect and efficiency of construction

How It Works (Installation Simplicity):

1. Position: Place the pre-fabricated detail (e.g., pipe boot) over the penetration.

2. Weld: Using a standard hot air welder, weld the flange of the detail directly onto the TPO /PVC base sheet or membrane.

3. Inspect: The result is a strong, permanent, and watertight bond that is as strong as the membrane itself.

Technical Data:

· Material: High-quality TPO PVC Polymer Blend

· Thickness: Matches standard TPO/PVC membrane thicknesses (e.g., 60 mil, 80 mil)

· Welding Method: Hot Air Welding

· Compatibility: Designed for use with all major TPO/PVC membrane brands and systems.

· Standards: Meets or exceeds ASTM and international roofing standards.

Upgrade your roofing system with the efficiency and reliability of pre-fabricated TPO/PVC details. Contact us today to find the right components for your project.