Hot Sale Roofing Materials TPO Waterproofing Membrane

Thermoplastic polyolefin (TPO) waterproof membrane is made of TPO resin by chemical copolymerization with specific formula .It is one of the

best materials using for roof waterproofing now

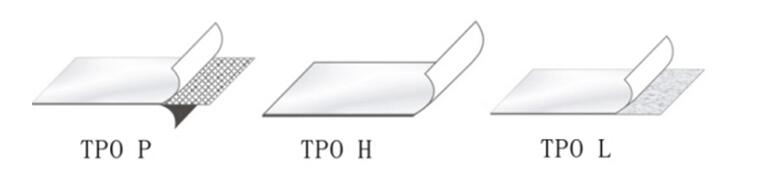

Classification &Specification

|

Type |

Color |

Thickness |

Width |

Length |

|

Homogeneous /Polyester Reinforced /Fleeced /Self adhesive / Preapplied Sand Type |

White Surface &Grey Backing or customized |

1.2mm /1.5mm /1.8mm /2.0mm |

2m/ 2.5m |

20m |

Key Features & Benefits

* Superior Heat-Welded Seams:

* Seams are fused using automatic hot-air welders, creating a permanent, monolithic, and homogenous bond that is as strong as the membrane itself. This eliminates the primary failure point of mechanically fastened or adhered systems, ensuring a completely watertight seal.

* Exceptional Energy Efficiency:

* The standard white, reflective surface reflects solar radiation, significantly reducing the "Heat Island" effect and lowering rooftop temperatures. This can lead to substantial savings on air conditioning costs and improve building energy efficiency.

*Outstanding Durability & Resistance:

* Reinforced Core:** A high-tenacity polyester scrim provides exceptional tensile strength, puncture resistance, and dimensional stability.

* UV & Ozone Resistance:** Formulated to withstand long-term exposure to sunlight and atmospheric pollutants without cracking or degrading.

* Chemical Resistance:** Resists a wide range of chemicals, oils, and fats commonly found on industrial and commercial sites.

* Environmentally Friendly & Safe:

* TPO is a environmentally conscious choice that contains no chlorine (unlike PVC), making it safe to produce and install. It is also fully recyclable at the end of its long service life, contributing to green building and LEED certification goals.

* Proven Weather Resistance:

* Excellent performance in extreme weather conditions, from high winds to freezing temperatures, maintaining its flexibility and strength to accommodate normal structural movement.

Typical Applications

Our TPO membrane is versatile and designed for a wide range of applications:

* Commercial & Industrial Roofs: New construction and re-roofing projects.

* Low-Slope & Flat Roofs: Ideal for slopes where water drainage is managed.

* Roofing Retrofit: Can often be installed over existing roof systems.

* Parking Decks & Plaza Decks: (When used as part of a protected membrane system).

* Educational, Healthcare, and Institutional Buildings.

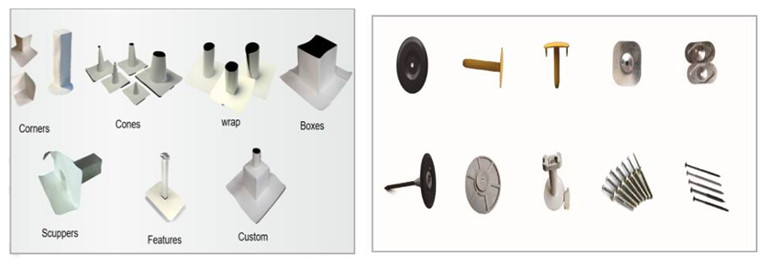

Application Tools

Quality Control

We implement a rigorous quality control system throughout the entire manufacturing process of our waterproofing membranes, from raw material intake to finished product dispatch.

Every batch of raw materials undergoes stringent chemical and physical property checks to ensure consistency and premium quality. During production, advanced online monitoring systems

continuously track key parameters like thickness and uniformity. Finally, each lot of rolls is subjected to comprehensive performance tests, including tests for tensile strength, tear resistance,

and weather resistance, to verify it meets or exceeds industry standards. This end-to-end quality assurance guarantees that every product leaving our facility is reliable and high-performing, providing you with complete peace of mind.

Storage and Transportation

●Moving, transporting,storing and using materials should avoid objects and environments which easily cause perforation or physical damage

●Different types of products should be classified and stored in parallel, with a height of no more than 5 layers

●The finished products should be sealed and packed using clean waterproof cloth to protect,and put it in a high place, such as pallet or wood

●All flammable materials should be stored in a cool and dry place, far from spark and fire .