Heat-Weldable TPO /PVC Prefabricated Details & Flashings

Streamline Installation, Ensure Perfection.

Our collection of pre-fabricated TPO details/PVC details is engineered to eliminate the complexities and potential failures associated with field-fabricated flashings. Manufactured from high-quality TPO PVC membrane, these components are ready to be heat-welded directly to your TPO roofing system and PVC rooing system , creating a monolithic, durable, and fully watertight barrier.

Key Features & Benefits:

· Seamless Integration: Made from the same high-quality TPO /PVC material as our membranes, ensuring perfect chemical and physical compatibility. They heat-weld together to form a single, homogeneous layer.

· Unmatched Consistency & Quality: Factory-controlled manufacturing guarantees uniform thickness, precise angles, and consistent quality, far superior to on-site fabrication.

· Dramatically Reduced Installation Time: Pre-formed shapes mean no cutting, folding, or guessing. Simply position and weld. This saves significant labor hours and gets your project watertight faster.

· Enhanced Reliability & Performance: Eliminate common weak points in roofing systems. Our prefabricated details are designed to withstand thermal movement, UV exposure, and harsh weather conditions, providing long-term peace of mind.

· Wide Range of Applications: Ideal for all commercial, industrial, and institutional buildings requiring a reliable and efficient single-ply roofing solution.

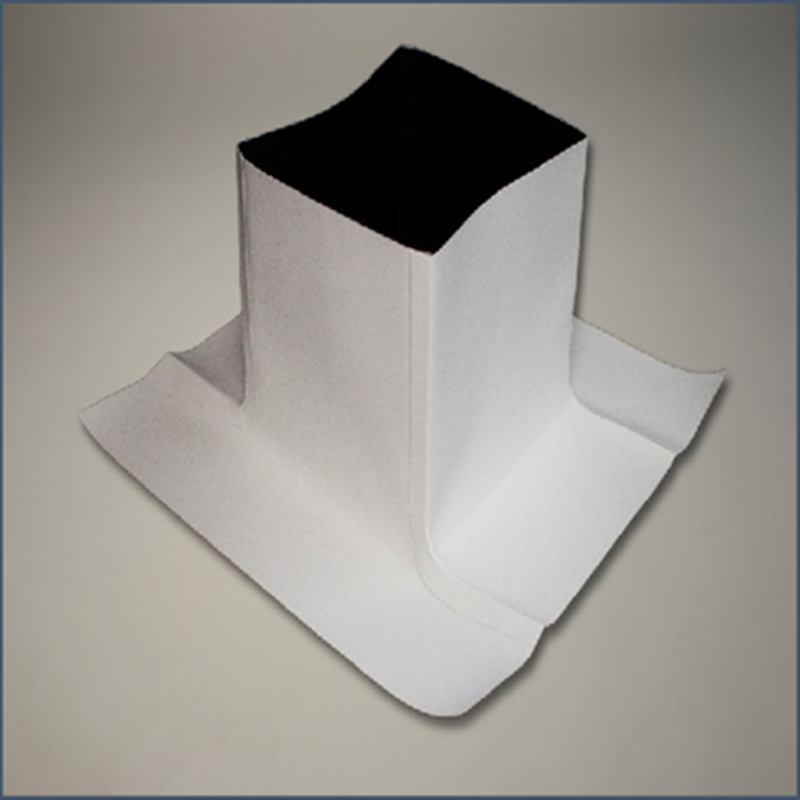

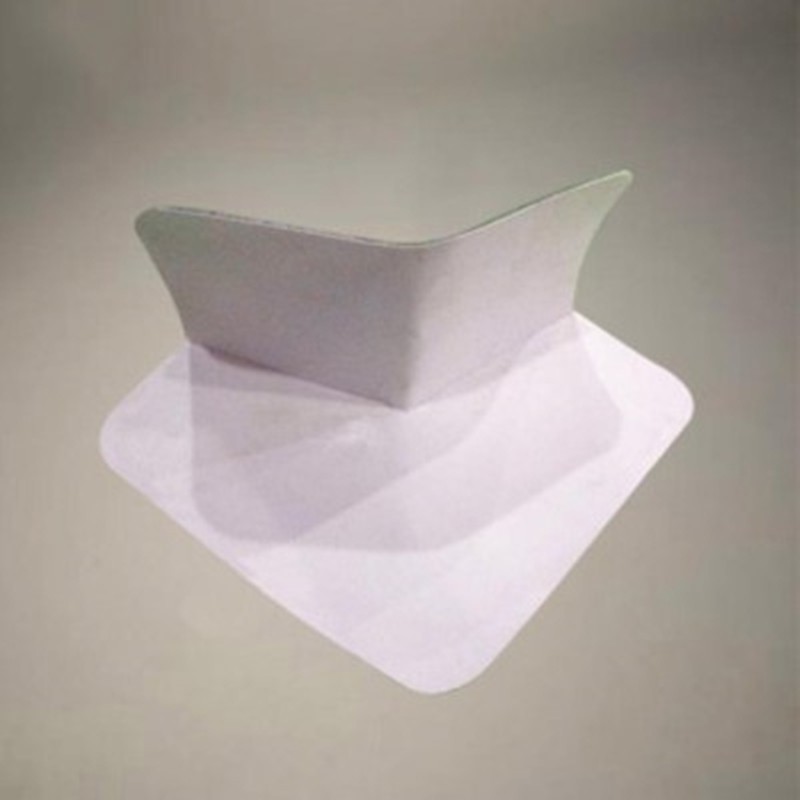

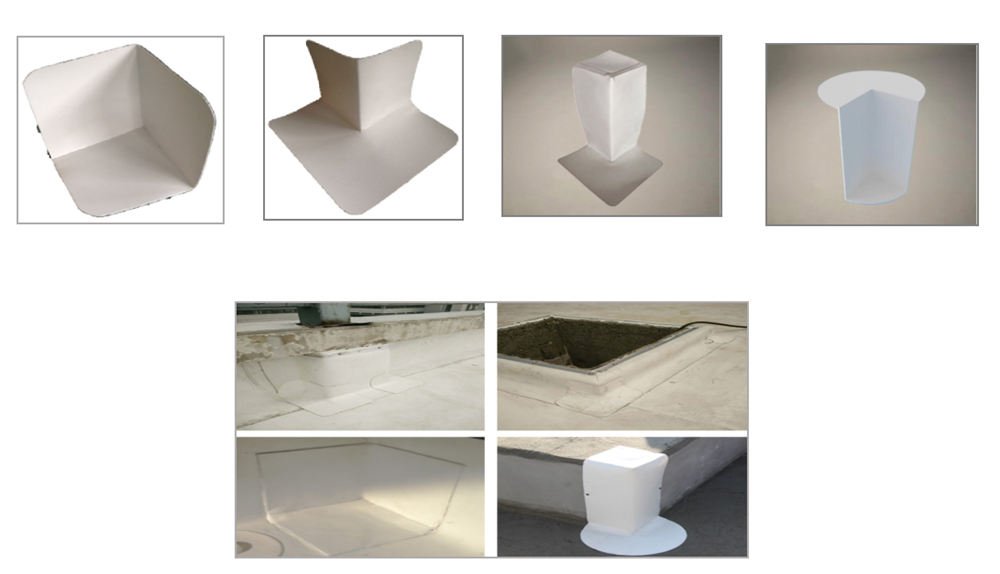

Product Range Includes:

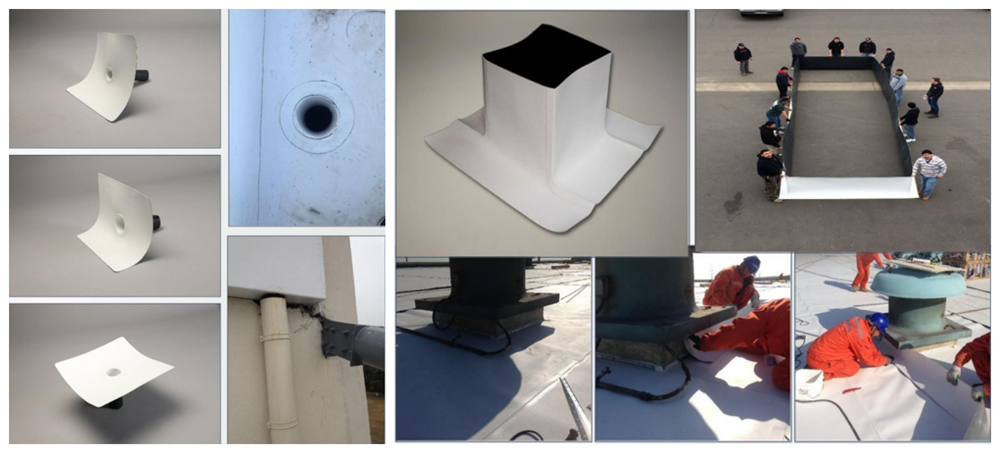

· Pipe Boots: Available in various sizes to fit standard roof penetrations. Ensures a perfect seal around pipes, conduits, and vents.

· Inside & Outside Corners: Pre-formed 90-degree corners for perfect seals at parapet walls, expansion joints, and other wall-to-roof transitions.

· Drain Sumps & Flashings: Specifically designed to create a robust, leak-proof seal around roof drains, the most critical detail in any roofing system.

· Custom Prefabricated Details: We can manufacture custom shapes to meet the specific requirements of your project.

How It Works (Installation Simplicity):

1. Position: Place the pre-fabricated detail (e.g., pipe boot) over the penetration.

2. Weld: Using a standard hot air welder, weld the flange of the detail directly onto the TPO /PVC base sheet or membrane.

3. Inspect: The result is a strong, permanent, and watertight bond that is as strong as the membrane itself.

Technical Data:

· Material: High-quality TPO PVC Polymer Blend

· Thickness: Matches standard TPO/PVC membrane thicknesses (e.g., 60 mil, 80 mil)

· Welding Method: Hot Air Welding

· Compatibility: Designed for use with all major TPO/PVC membrane brands and systems.

· Standards: Meets or exceeds ASTM and international roofing standards.

Upgrade your roofing system with the efficiency and reliability of pre-fabricated TPO/PVC details. Contact us today to find the right components for your project.