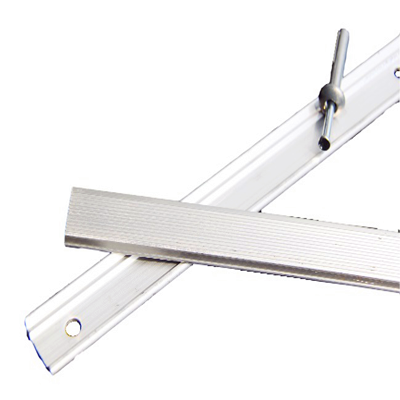

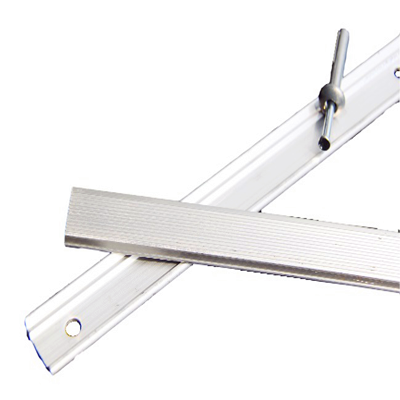

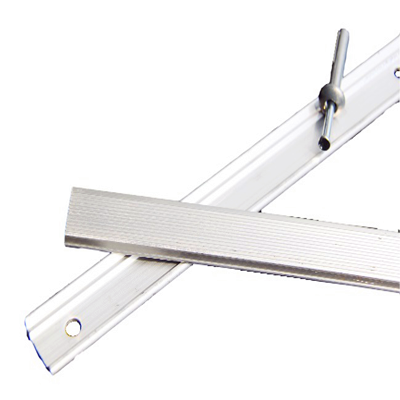

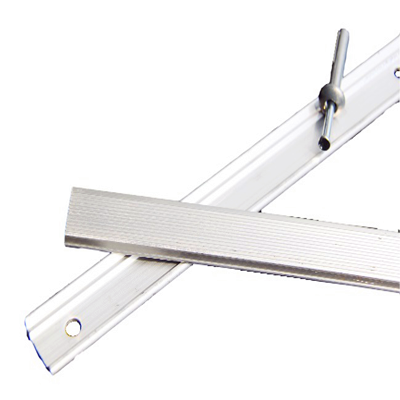

Our TPO/PVC Termination Bar is a critical component for completing and securing single-ply roofing systems. This heavy-duty aluminum bar is designed to mechanically fasten and seal the loose ends of TPO or

PVC roofing membranes at roof edges, parapet walls, penetrations, and terminations. It provides a clean, secure, and weatherproof finish, ensuring the integrity of the roof assembly and preventing wind uplift and water infiltration.

Key Features & Benefits:

* Secure Mechanical Fastening: Provides a robust, mechanical lock for the membrane, preventing it from pulling loose under wind uplift forces or thermal contraction/expansion.

* Superior Weather Seal: Used in conjunction with a compatible sealant, it creates a watertight and airtight seal at critical termination points, protecting the building interior from moisture damage.

* Durable & Corrosion-Resistant: Manufactured from high-grade anodized aluminum, ensuring exceptional resistance to rust and corrosion for the life of the roof.

* Clean, Professional Finish: Creates a straight, neat termination line, enhancing the overall aesthetics and professionalism of the roof installation.

* Universal Compatibility: Specifically engineered for use with Thermoplastic Polyolefin (TPO) and Polyvinyl Chloride (PVC) roofing membranes.

* Easy Installation: The pre-drilled holes allow for quick and straightforward screw-fastening into the substrate. The design securely clamps the membrane without cutting or damaging it.

Applications & Use Cases:

This termination bar is essential for securing the membrane at:

* Roof Perimeter and gravel stops

* Parapet Walls and coping bases

* Roof Penetrations (pipes, conduits, curbs)

* Wall Terminations and expansion joints

* Door Thresholds and rooftop access points

Installation Guide

1. Position Membrane: Place the loose end of the TPO/PVC membrane over the edge of the substrate (e.g., parapet wall).

2. Apply Sealant: Run a continuous bead of compatible, non-staining sealant along the substrate.

3. Place Bar: Position the termination bar over the membrane, aligning it with the edge.

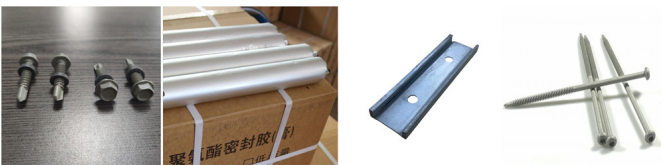

4. Fasten: Drive corrosion-resistant screws with neoprene washers through the pre-drilled holes in the bar, through the membrane, and into the substrate. The bar will compress the membrane and sealant, creating a watertight clamp.

5. Seal the Edge: Apply an additional bead of sealant over the top edge of the bar for a completely waterproof finish.

Why Choose Our Termination Bar?

* Engineered for Performance: Designed to meet and exceed industry standards for wind-uplift resistance.

* Long-Term Reliability: The corrosion-resistant aluminum construction ensures the bar will not fail, protecting your roof termination for decades.

* System Integrity: Ensures the entire roofing system is properly secured and sealed, a critical step for validation of manufacturer warranties.

* Professional Result: Guarantees a clean, durable, and code-compliant finish on every project.

Other Related Items :

Complete your TPO/PVC roofing system with confidence. Ensure a secure, lasting termination with our professional-grade fastening bars.