Pre-Applied, Bonded HDPE Waterproofing Membrane for Basement Slabs & Walls

---------The Definitive Below-Grade Waterproofing Solution

Our Pre-Applied Bonded HDPE Membrane is a revolutionary below-grade waterproofing system designed for installation before concrete is poured. Engineered specifically for basement slabs and retaining walls,

it creates a permanent, inseparable bond with the cast-in-place concrete structure. This "positive-side" application forms a "second skin" that eliminates water migration, providing unparalleled protection and long-term durability for your underground structures.

Specification

|

Thickness |

1.2mm |

1.5mm |

1.7mm |

|

Width |

2m |

2m |

2 |

|

Length |

20m |

20m |

20m |

Key Features & Benefits

Permanent, Positive Bond:

* The core technology lies in its bonding layer. Once the concrete is poured, it integrates with the membrane, creating a mechanical and chemical bond that is permanent and impossible to delaminate. This eliminates the risk of water migration(water traveling between the membrane and the structure), which is the primary failure point of traditional systems.

Superior Physical Protection:

*The high-density polyethylene (HDPE) core offers exceptional puncture and tear resistance, protecting against sharp aggregates, settlement, and construction abuse. It can bridge cracks in the substrate without compromising the waterproofing integrity.

Pre-Applied Installation for Efficiency:

* Installed directly onto the excavation sub-base or formwork, this method decouples waterproofing from other trades. This allows for faster project schedules, as waterproofing can proceed independently of weather delays and concurrently with rebar assembly.

Exceptional Chemical Resistance:

* HDPE is inert and highly resistant to a wide range of chemicals, alkalis, and acids found in soil and groundwater. It is also root-resistant and immune to microbial growth, ensuring long-term performance without degradation.

A Complete, Monolithic Barrier:

* Sheets are seamlessly joined using hot-air welded seams, creating a continuous, monolithic barrier without weak points. This provides a holistic solution for both horizontal slabs and vertical walls.

How It Works: The Bonded Advantage

1. Prepare & Place: The membrane is rolled out loosely onto the prepared sub-grade (for slabs) or temporary formwork (for walls).

2.Place Rebar & Pour Concrete: Reinforcement is placed directly on the membrane. Concrete is then poured directly onto it.

3. Form a Permanent Bond: The special surface of the membrane bonds inseparably with the fresh concrete as it cures, locking the waterproofing to the structure itself.

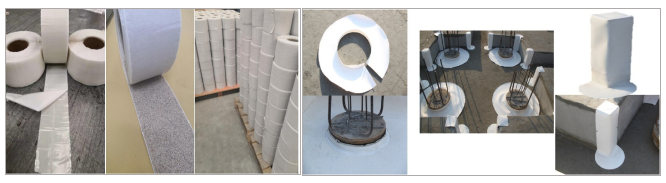

Supporting System

Ideal Applications

* New Construction Basement Slabs & Walls

* Underground Parking Garages

* Tunnels and Subway Stations

* Water Reservoirs and Treatment Plants

* Any below-grade concrete structure requiring the highest level of waterproofing security.

Quality Control

We implement a rigorous quality control system throughout the entire manufacturing process of our waterproofing membranes, from raw material intake to finished product dispatch. Every batch of raw materials undergoes stringent

chemical and physical property checks to ensure consistency and premium quality. During production, advanced online monitoring systems continuously track key parameters like thickness and uniformity. Finally, each lot of rolls is subjected

to comprehensive performance tests, including tests for tensile strength, tear resistance, and weather resistance, to verify it meets or exceeds industry standards. This end-to-end quality assurance guarantees that every product leaving our

facility is reliable and high-performing, providing you with complete peace of mind.

Packing &Logistics

Why Choose Our Pre-Applied HDPE System?

Traditional externally-applied membranes are vulnerable to damage during backfilling and require a perfect substrate. If a leak occurs, locating and repairing it is costly and disruptive.

Our Pre-Applied Bonded System makes the membrane an integral part of the structure itself. Even if the membrane is punctured from the outside, water cannot travel laterally, localizing any potential issue and making the system inherently more reliable and fail-safe.

This is more than just a product; it's a smarter, more resilient approach to below-grade waterproofing.

Contact us today to request a sample, a technical data sheet, or to speak with our engineering support team.