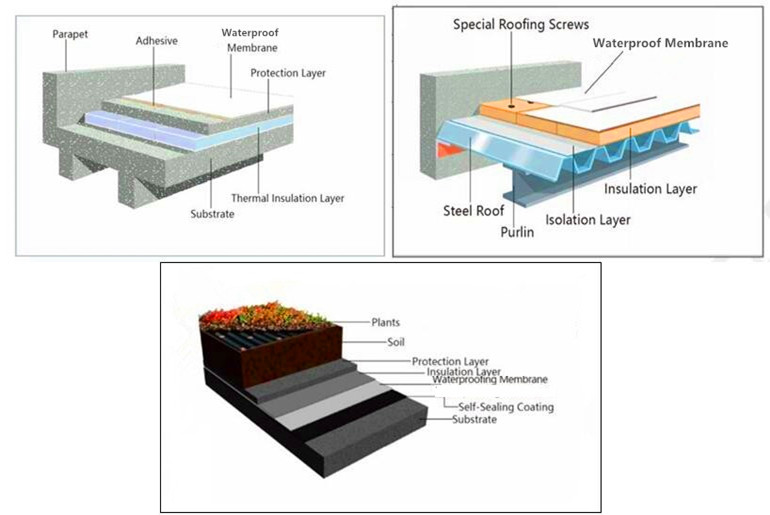

Polyvinyl chloride (PVC) waterproofing membrane is a type of new high macro-molecular waterproofing Cold-adhesive and hot-welding is both available when attending to the joint of membrane

|

Type |

Color |

Thickness |

Width |

Length |

|

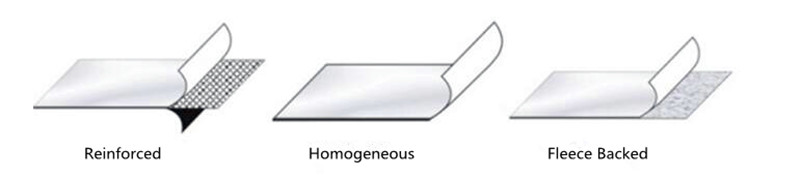

Homogeneous /Polyester Reinforced /Fleece Backing

|

White Surface &Grey Backing or customized |

1.2mm /1.5mm /1.8mm /2.0mm |

2m |

20m |

Application Method

Quality Control

We implement a rigorous quality control system throughout the entire manufacturing process of our waterproofing membranes, from raw material intake to finished product dispatch. Every batch of raw materials undergoes

stringent chemical and physical property checks to ensure consistency and premium quality. During production, advanced online monitoring systems continuously track key parameters like thickness and uniformity. Finally,

each lot of rolls is subjected to comprehensive performance tests, including tests for tensile strength, tear resistance, and weather resistance, to verify it meets or exceeds industry standards. This end-to-end quality

assurance guarantees that every product leaving our facility is reliable and high-performing, providing you with complete peace of mind.

Storage &Transportation

Why Choose Our PVC Waterproofing Membrane?

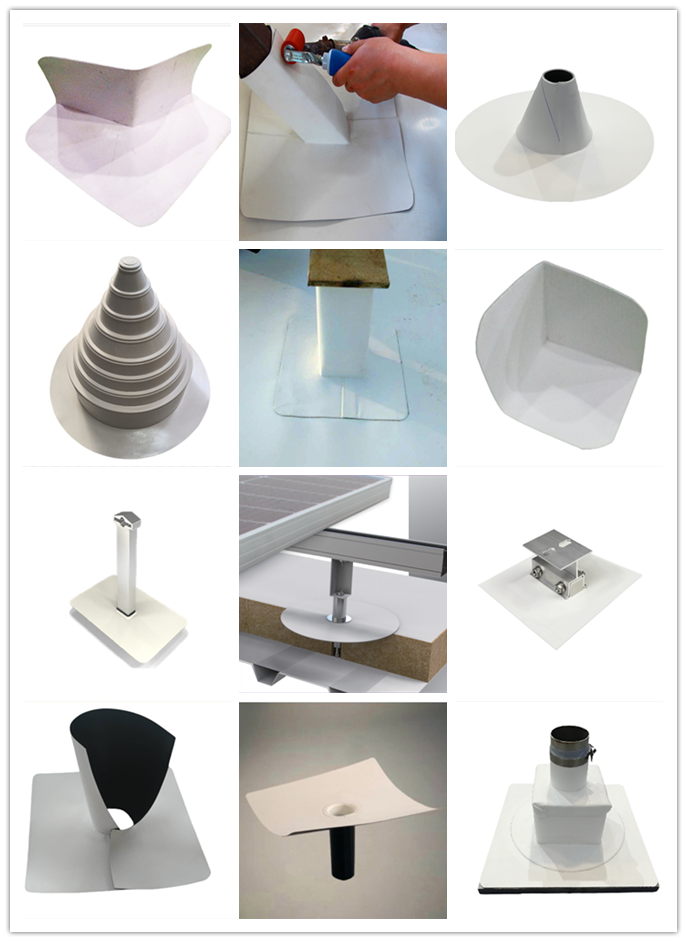

Unlike rudimentary waterproofing methods, our PVC membrane provides a engineered, systematic solution. The combination of a reinforced core, superior chemical formulation, and the integrity

of heat-welded seams creates a monolithic barrier that is designed to last for decades with minimal maintenance. It represents the optimal balance of performance, cost-effectiveness, and installation efficiency for modern construction projects.

Contact Us

Request a free sample or contact our technical support team to discuss your specific project requirements and receive a detailed datasheet.