Factory Offer Cheap Aluminum Faced Butyl Rubber Tape

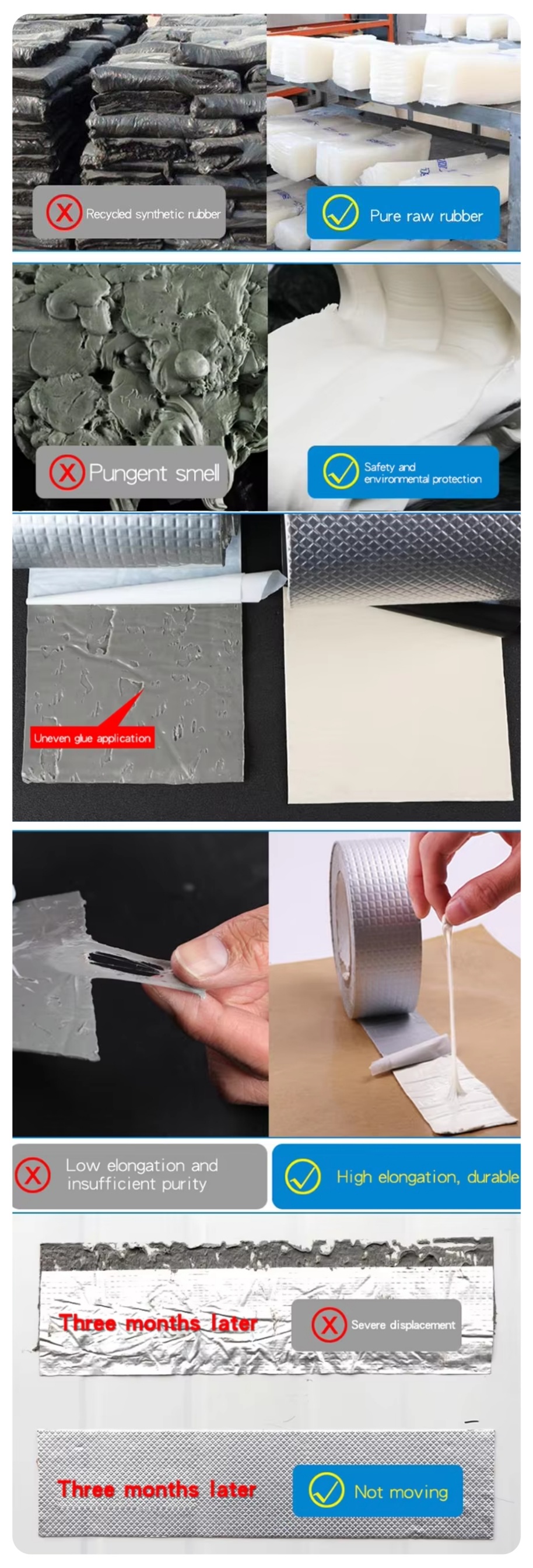

Waterproof butyl rubber tape using butyl rubber as backing, choosing excellent high molecular material and produced by special processing. Environment friendly, solvent free

and not solidify permanently.

Classification &Specification

Pain Points & Solution

Tired of Costly Leaks? - Water damage can ruin your RV interior Hate Complicated Repairs? - No need for liquid sealants, torches, or professionals.

Sick of Short-Lived Fixes? - Cheap tapes fail quickly under sun and rain.

Your Simple & Permanent Solution: Butyl Aluminum Foil Tape!

Key Features

* 100% Waterproof & Airtight:Butyl rubber core creates a permanent barrier against water and air infiltration.

* Superior UV & Weather Resistance: Aluminum foil reflects UV rays and withstands extreme temperatures (-40°C to 90°C).

* Excellent Adhesion & Conformability: Bonds strongly to metal, PVC, wood, and concrete; contours to irregular surfaces.

* Corrosion & Chemical Resistance: Protects seams and joints from corrosive elements.

* Durable & Long-Lasting:Engineered for permanent repairs, no cracking or shrinking over time.

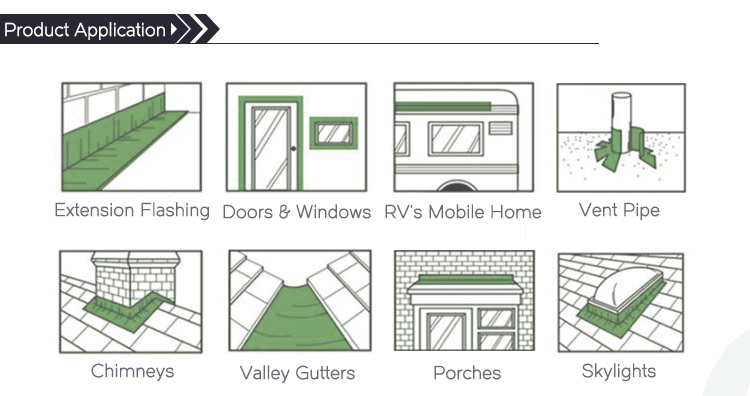

*The connection of steel roof color plate and roof lighting sheet, sealing of gutter joint.

*The sealing and waterproof of windows, doors, concrete roof, vent line etc.

*The install of PC sheet.

*The adhesion of waterproof film of car door and window, sealing and shock proof.

The difference between good and bad quality butyl tape

Technical Specifications

Material: Butyl Rubber Base + Aluminum Foil

Thickness:0.5mm-0.7mm-0.8mm-0.9mm-1.0mm-1.2mm-1.5mm

Product Width.:

5cm-7.5cm-10cm-15cm-20cm-50cm-100cm(all can be customized)

Product Length: 5m-10m (all can be customized)

Installation Guide

1: Surface Preparation - Clean and dry the surface thoroughly. Remove all dust, oil, and loose particles.

2: Unroll & Cut - Unroll the tape and cut to the desired length.

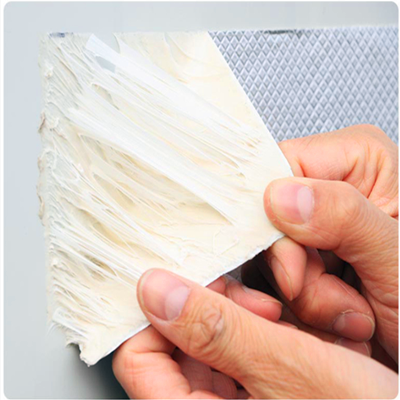

3: Peel & Apply - Remove the release film and firmly press the tape onto the surface.

4: Firm Pressure - Use a roller or hand to apply strong pressure, especially along the edges, to ensure complete contact.

Quality Control

We implement a rigorous quality control system throughout the entire manufacturing process of our waterproofing membranes, from raw material intake to finished product dispatch.

Every batch of raw materials undergoes stringent chemical and physical property checks to ensure consistency and premium quality. During production, advanced online monitoring systems

continuously track key parameters like thickness and uniformity. Finally, each lot of rolls is subjected to comprehensive performance tests, including tests for tensile strength, tear resistance,

and weather resistance, to verify it meets or exceeds industry standards. This end-to-end quality assurance guarantees that every product

Notice:

a. Surface must be dry and clean (remove any moisture, grease and dust);

b. Butyl tape should be stored at room temperature and normal humidity, and keep away from sunshine and hot air;

c. One time application can make sure its best performance.

Packing & Shipping

Packing:10m/roll, 20m/roll, 50m/roll. Individually wrapped in plastic film, then in carton boxes.