Underground Projects Hdpe Self Adhesive Waterproof Membrane price

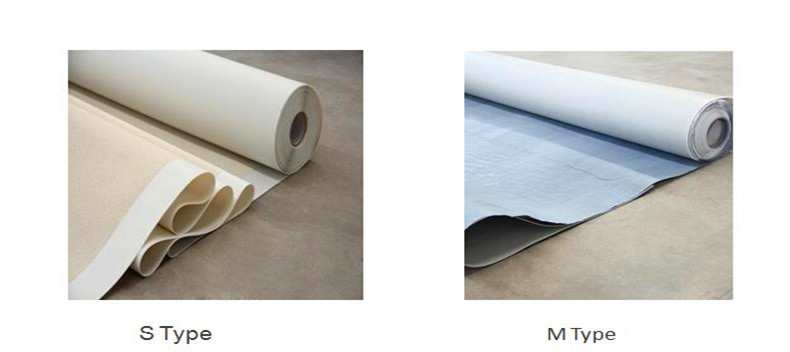

HDPE pre-applied waterproof membrane is made of three layers of materials,which are HDPE sheet, hot-melt pressure sensitive adhesive, and isolating

material respectively. And the isolating material can be special sand(type S) and isolation membrane(type M)

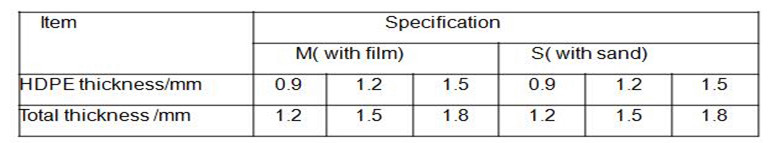

Classification &Specification

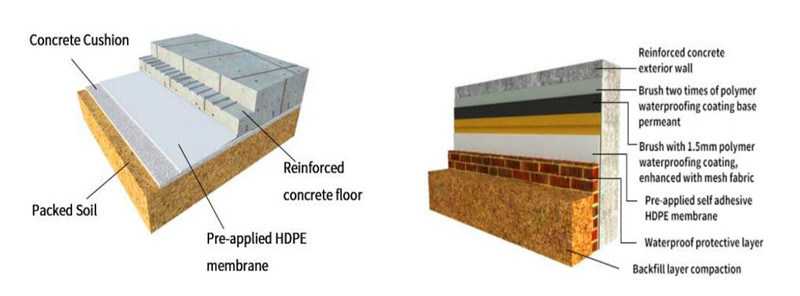

Waterproof and anti-seepage for all kinds of underground projects ,such as tunnels , subway, basement ,bridge etc

1.Pre-applied full-bonding installation: the HDPE pre-applied membrane sanding surface up temporary fixed on the bottom cushion. Direct binding reinforcement,

and then poured concrete. The membrane coated sand layer will combine with it tightly ,no water moving between layers.

2.It has strong self-healing ability and can repair slight construction injury.7.The floor board of the building should be constructed with a pre-applied anti-sticking method. This method no need protective layer.

Supporting System

Application Method

Quality Control

We implement a rigorous quality control system throughout the entire manufacturing process of our waterproofing membranes, from raw material intake to finished product dispatch. Every batch of raw materials

undergoes stringent chemical and physical property checks to ensure consistency and premium quality. During production, advanced online monitoring systems continuously track key parameters like thickness and uniformity.

Finally, each lot of rolls is subjected to comprehensive performance tests, including tests for tensile strength, tear resistance, and weather resistance, to verify it meets or exceeds industry standards. This end-to-end quality

assurance guarantees that every product leaving our facility is reliable and high-performing, providing you with complete peace of mind.

4 All flammable materials should be stored in a cool and dry place, far from spark and fire .