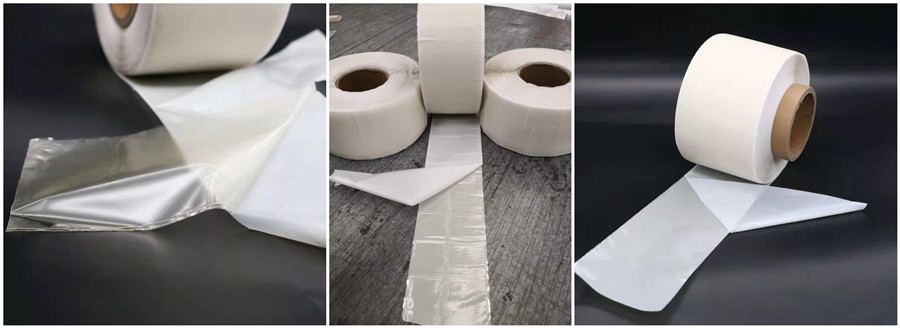

HDPE Sealing Tape for Overlapping Areas

Double Side adhesive HDPE sealing tape is mainly used for HDPE membrane Overlap Connection .

This tape features a robust HDPE carrier film coated on both sides with a powerful, pressure-sensitive adhesive. It is designed to form a permanent bond that withstands the

harsh conditions of underground environments, including ground moisture, chemical exposure, and long-term static loads. The simple peel-and-stick application eliminates

the need for heat welding or liquid adhesives, significantly reducing installation time and labor costs while ensuring a consistent and reliable seal.

It is a cold applied, self- adhesive tape. Both sides are covered with highly aggressive, pressure-sensitive adhesive (PSA), which has perfect bonding performance with HDPE membrane and concrete, both sides are protected by PE/PET release film.

Product features

*Excellent Waterproof Sealing: Provides a fully waterproof secondary seal, effectively preventing water infiltration and protecting underground structures.*

*Perfect Compatibility with HDPE: Specifically designed for HDPE materials, ensuring superior bond strength and long-term durability, preventing debonding due to material incompatibility.

* Chemical and Aging Resistance: Resists degradation from common chemicals, microorganisms, and salts found in soil, offering stable performance and an extended service life.

* Easy and Efficient Installation: The self-adhesive design requires only surface cleaning, release paper removal, alignment, and firm pressing. No need for specialized welding equipment or highly skilled labor.

*High Bond Strength: Offers high peel and shear strength, creating a robust seam comparable to heat welding, ensuring the integrity of the lap joint.

Specification

Double side adhesive tape :

0.9mm thickness 8cmX25/ Roll ,9Rolls /Carton

0.9mm thickness 10cmx25m/ Rolls , 6 rolls/carton

Packging & Logistics

Sealed and stored in a cool and dry place, avoiding direct sun and rain exposure;

Storage time is 6 months from manufactured date.

Quality Control

We implement a rigorous quality control system throughout the entire manufacturing process of our waterproofing membranes, from raw material intake to finished product dispatch. Every batch of raw materials undergoes stringent chemical and physical property checks to ensure consistency and premium quality. During production, advanced online monitoring systems continuously track key parameters like thickness and uniformity. Finally, each lot of rolls is subjected to comprehensive performance tests, including tests for tensile strength, tear resistance, and weather resistance, to verify it meets or exceeds industry standards. This end-to-end quality assurance guarantees that every product leaving our facility is reliable and high-performing, providing you with complete peace of mind.

Contact Us